With the improvement of living standards, people’s demand for goods are gradually increasing, and the number of goods in stock of enterprises are also increasing. Therefore, how to effectively use the limited storage space to make the function better has become a problem that many enterprises are concerned . However, if you blindly pursue the density of storage , it will affect the efficiency of warehouse. If more goods storage are required, more intensive storage are necessary, so that the warehouse space can be used more efficiently.

To achieve intensive storage, the focus is on:

1. Make full use of the vertical space of the warehouse:

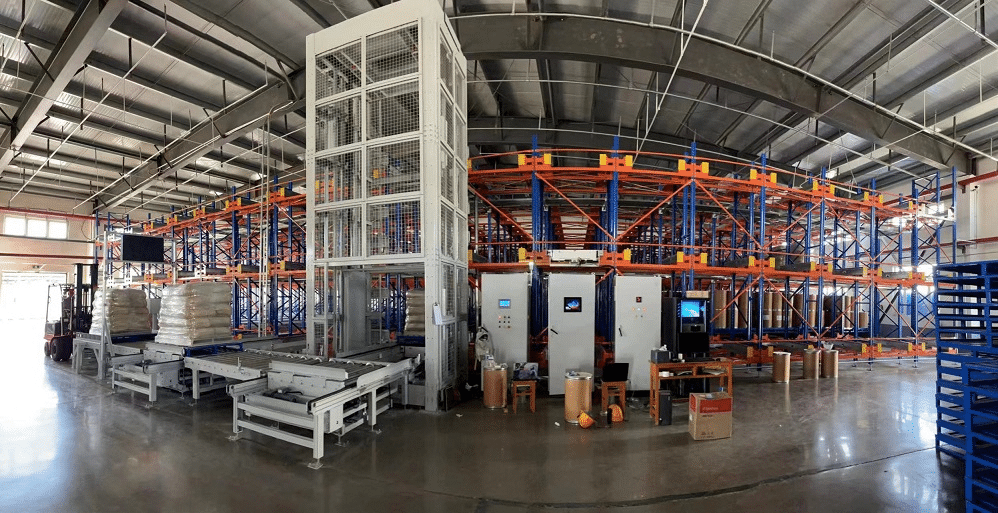

From the perspective of warehouse utilization, automated storage systems are the most typical. According to statistics, the storage capacity per unit area of the automated three-dimensional warehouse can reach up to 7.5 tons, which is equivalent to more than five times that of ordinary rack. With the advantages of high space utilization rate and high automatic access efficiency, it has become the first choice for industries such as electronics, medicine, food, and chemical industry.

2. Appropriate channel width:

The racks that realize intensive storage are mainly include drive-in racks, shuttle racks, narrow aisle racks, and four-way intelligent intensive storage system. All of these increase the floor space ratio of warehouses by reducing forklift operation aisles or increasing mechanized operations. The shuttle rack is a kind of storage rack purchased by many customers in recent years. It is characterized in that the pallet shuttle is used to store and place goods in the operation lane, and the shuttle can be used together in multiple lanes, and the location of the shuttle can be moved by a forklift. and store goods. If customers have information technology and the aspect of intelligent demand, they can use four-way intelligent intensive storage system to realize fully automated intensive storage of goods, without the need to reserve a channel for forklifts to travel in between the goods.

3. Channel and height are compatible with each other:

Multi-layer shuttle racks are representative in terms of racking channels and height compatibility. It has the characteristics of sorting, picking, and automatically transporting goods. The space of other warehouses can be fully utilized, which are not only saves aisle space, but also saves the area ratio of racks with the same height.

In the case of a wide variety of goods and a large storage volume, it is an inevitable trend to realize intensive storage. Many forward-looking companies in China have already started research on automatic storage equipment. Nanjing Four-way Intelligent Storage Equipment Co., Ltd. is a production-oriented enterprise specializing in R&D and production of radio shuttle and four-way intelligent shuttle system. It has a complete system research and development process starting from 0 for five years, and has achieved two critical Invention Patents, and a standardized system has also been formed.

Through automated storage, enterprises can greatly reduce storage costs, thereby improving data availability and reliability, and providing more scalability for the enterprises development.

Post time: Apr-26-2023