-

AMR

AMR trolley, it is a transport vehicle equipped with automatic guidance devices such as electromagnetic or optical, which can travel along the prescribed guiding path, has safety protection and various transfer functions. In industrial applications, it is a transport vehicle that does not require a driver. Its power source is a rechargeable battery.

Submerged AMR: sneak into the bottom of the material truck, and automatically mount and separate to realize material delivery and recycling operations. Based on various positioning and navigation technologies, automatic transport vehicles that do not require human driving are collectively referred to as AMR.

-

Palletizer

The palletizer is the product of the organic combination of machinery and computer programs,it Improves the efficiency of modern production. Palletizing machines are widely used in the palletizing industry. Palletizing robots can greatly save labor cost and floor space.

The palletizing robot is flexible, precise, fast, efficient, stable and efficient.

The palletizing robot system uses a coordinate robot device, which has the advantages of small footprint and small volume. The idea of establishing an efficient, efficient and energy-saving fully automated block machine assembly line can be realized.

-

Tray folding machine

Tray folding machine is an automatic equipment, which is also called code tray machine, it’s used in tray conveying system, combined with various conveyors, to distribute empty trays to the conveying line. The tray folding machine is used to stack single pallets into pallets stacking, including: pallet stacking support structure, pallet lifting table, load sensor, pallet position detection, open/close robot sensor, lift, lower, central position switch.

-

RGV

RGV stands for Rail Guide Vehicle, is also called a trolley. RGV is used in warehouses with various high-density storage methods, and the aisles can be designed according to any length to increase the storage capacity of the entire warehouse. In addition, when working, you can also take advantage of the fact that the forklift does not need to enter the lane way, combined with the rapid movement of the trolley in the lane way, it can effectively improve the operational efficiency of the warehouse and make it more safety.

-

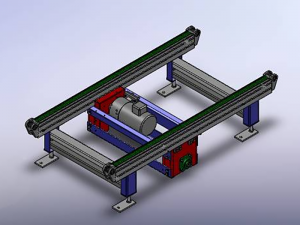

Information 4D shuttle conveyor system

The motor drives the drive shaft through the transmission group, and the drive shaft drives the conveying chain to realize the conveying function of the pallet.