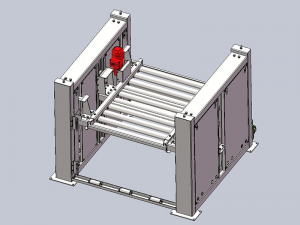

Information 4D shuttle conveyor system

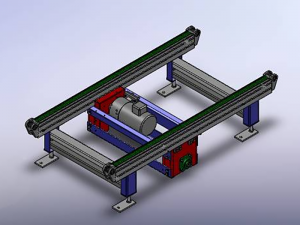

chain conveyor

| project | Basic data | Remark |

| model | SX-LTJ-1.0T -600H | |

| Motor reducer | SEW | |

| structure type | The frame is made of aluminum alloy, and the legs and bends are made of carbon steel | |

| control method | Manual/stand-alone/online/automatic control | |

| security measures | Electrical interlock, protective guides on both sides | |

| adopt the standard | JB/T7013-93 | |

| payload | Max 1000KG | |

| cargo inspection | Photoelectric Sensors | SICK/P+F |

| chain track | Low friction nylon track | |

| conveyor chain | Donghua Chain | |

| bearing | Fukuyama Hardware, Sealed Ball Bearings | |

| transfer speed | 12m/min | |

| Surface Treatment and Coating | Pickling, phosphating, spraying | |

| noise control | ≤73db | |

| surface coating | computer gray | Attached swatches |

Equipment structure

The conveyor is composed of frame, outriggers, drive unit and so on. The frame is made of aluminum alloy, and both ends are fixed toothless reversing wheels. The conveyor chain is straight double-row chain with pitch P=15.875mm. The chain support is made of high molecular polyethylene (UHMW) with self-lubricating effect. The welded outriggers are connected with the main frame by the bolt pressure plate, the M20 screw adjustment feet are connected with the ground, and the height of the conveying surface can be adjusted by +25mm. The driving device is composed of a built-in deceleration motor in the middle, a drive shaft assembly, a transmission sprocket set, a motor seat and a chain tensioning device , and the screw-type adjusting tensioner pulley tensions the conveying chain.

working principle:

The motor drives the drive shaft through the transmission group, and the drive shaft drives the conveying chain to realize the conveying function of the pallet.

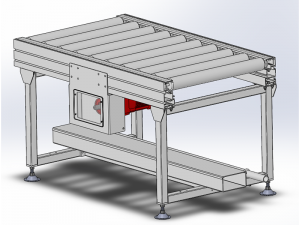

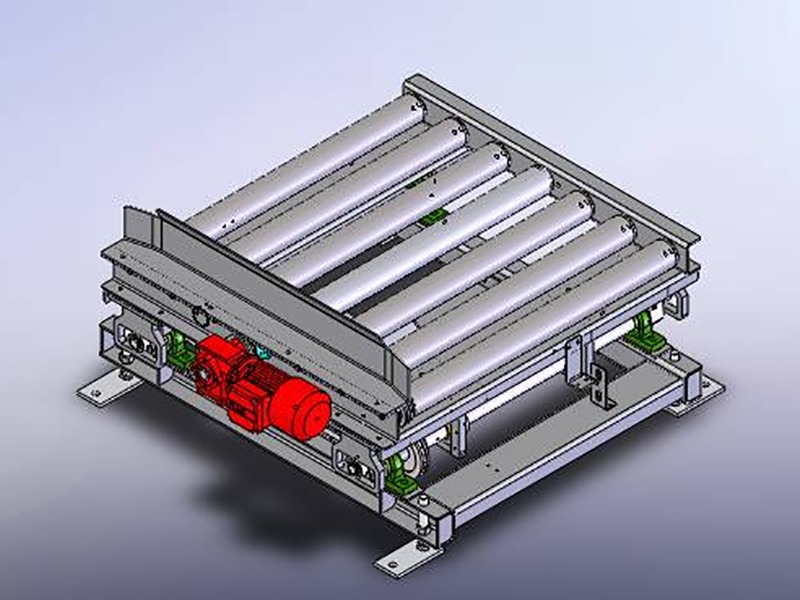

Roller conveyor

| Item | Basic data | Remarks |

| Model | SX-GTJ-1.0T -600H | steel structure |

| Motor reducer | SEW | |

| structure type | carbon steel bending | |

| control method | Manual/stand-alone/online/automatic control | |

| payload | Max 1000KG | |

| transfer speed | 12m/min | |

| roller | 76 double chain roller | |

| drive chain | Huadong Chain Factory | |

| bearing | Ha axis | |

| Surface Treatment and Coating | Pickling, phosphating, spraying | |

Equipment structure

Equipment structure: The roller table machine is composed of a frame, outriggers, rollers, drives and other units. Roller φ76x3 single side double sprocket galvanized roller, roller spacing P=174.5mm, single side double sprocket. The welded outriggers are connected with the main frame by the bolt pressure plate, the M20 screw adjustment feet are connected with the ground, and the height of the conveying surface can be adjusted by +25mm. The driving device is composed of a built-in deceleration motor in the middle, a transmission sprocket set, a motor seat and a chain tensioning device.

Working principle: The motor drives the roller through the chain, and the roller is transmitted to the adjacent roller through another chain, and then to another roller to realize the conveying function of the conveyor .

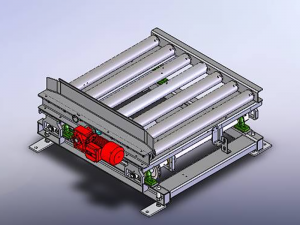

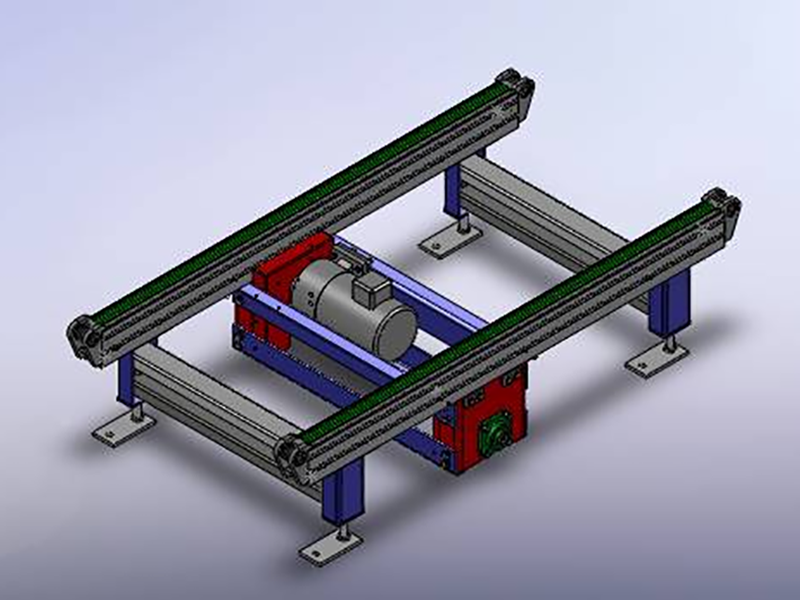

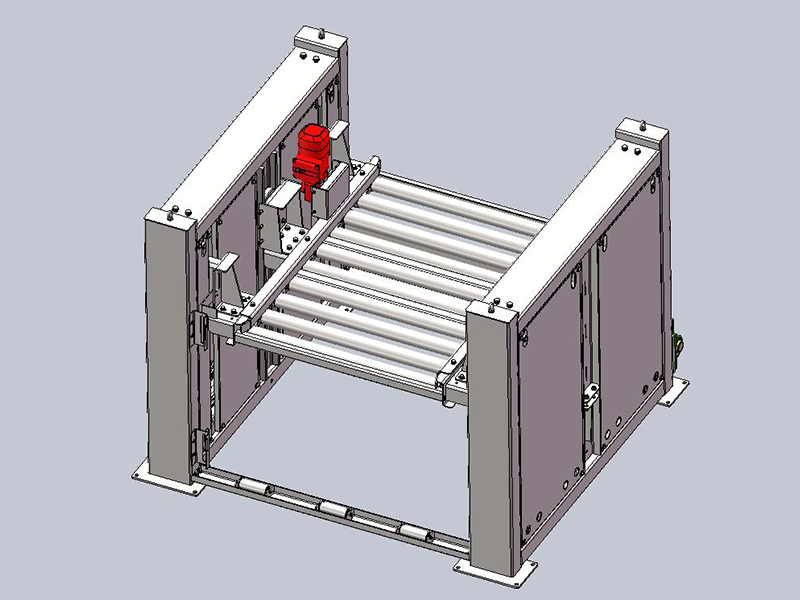

Jacking and transfer machine

| project | Basic data | Remark |

| model | SX-YZJ-1.0T-6 0 0H | steel structure |

| Motor reducer | SEW | |

| structure type | carbon steel bending | |

| control method | Manual/stand-alone/online/automatic control | |

| security measures | Electrical interlock, protective guides on both sides | |

| Standard | JB/T7013-93 | |

| payload | Max 1000KG | |

| cargo inspection | Photoelectric Sensors | SICK/P+F |

| roller | 76 double chain roller | |

| Bearings and housings | Bearing: Harbin shaft; Bearing seat: Fushan FSB | |

| transfer speed | 12m/min | |

| Surface Treatment and Coating | Pickling, phosphating, spraying | |

| noise control | ≤73dB | |

| surface coating | computer gray | Attached swatches |

Equipment structure

Equipment structure: The roller transfer machine is composed of conveying parts, lifting mechanisms, guiding components and other units. Conveying surface height adjustment +25mm. The lifting mechanism adopts the principle of motor-driven crank arm, and the driving device is composed of a built-in reduction motor in the middle, a transmission sprocket set, a motor seat and a chain tensioning device.

Working principle: When the pallet is conveyed to the equipment by the matching conveyor, the jacking motor runs, driving the cam mechanism to lift the pallet, and the jacking motor stops when it is in place; the conveying motor starts, conveying the pallet to the docking equipment, and The motor stops, the jacking motor runs, and the cam mechanism is driven to lower the equipment, and when it is in place, the jacking motor stops to complete a working cycle.

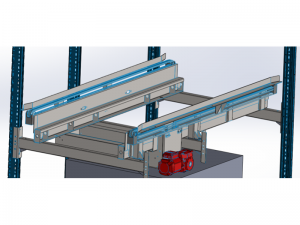

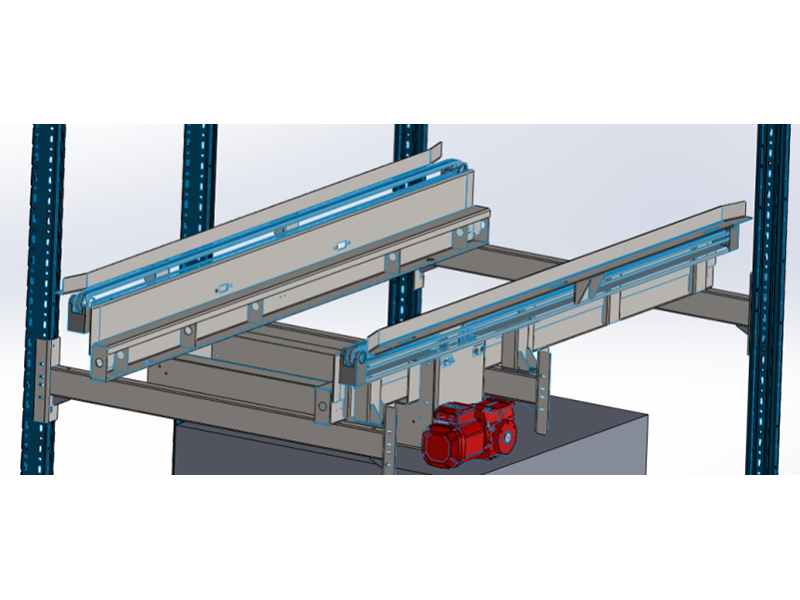

Transition conveyor

| 1) project | Basic data | Remark |

| model | SX-GDLTJ-1.0T-500H-1.6L | |

| Motor reducer | SEW | |

| structure type | Legs and bent carbon steel | |

| control method | Manual/stand-alone/online/automatic control | |

| security measures | Electrical interlock, protective guides on both sides | |

| Standard | JB/T7013-93 | |

| payload | Max 1000KG | |

| cargo inspection | Photoelectric Sensors | SICK/P+F |

| chain track | Low friction nylon track | |

| conveyor chain | Donghua Chain | |

| Bearings and housings | Bearing: Harbin shaft, bearing seat: Fukuyama FSB | |

| transfer speed | 12m/min | |

| Surface Treatment and Coating | Pickling, phosphating, spraying | |

| noise control | ≤73dB | |

| surface coating | computer gray | Attached swatches |

Equipment structure

Equipment structure: This equipment is used at the joint between the hoist and the shelf, and the conveyor is composed of a frame, outriggers, and a drive unit. The conveyor chain is straight double-row chain with pitch P=15.875mm. The chain support is made of high molecular polyethylene (UHMW) with self-lubricating effect. Welded legs, connected to the shelf body. The driving device is composed of a built-in deceleration motor in the middle, a drive shaft assembly, a transmission sprocket set, a motor seat and a chain tensioning device, and the screw-type adjusting tensioner pulley tensions the conveying chain.

Working principle : The motor drives the drive shaft through the transmission group, and the drive shaft drives the conveying chain to realize the conveying function of the pallet.

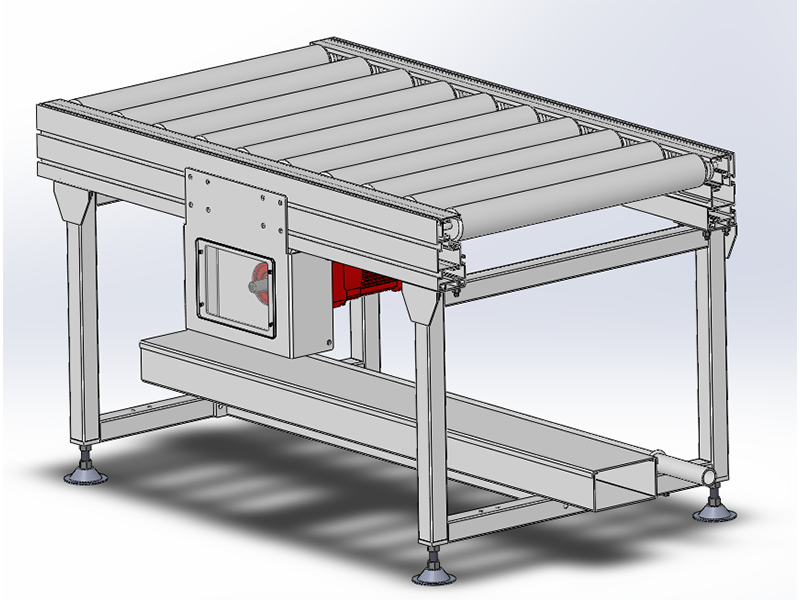

floor lift

| project | Basic data | Remark |

| model | LDTSJ-1.0T-700H | steel structure |

| Motor reducer | SEW | |

| structure type | Column: carbon steel bending Outer side: steel plate seal | |

| control method | Manual/stand-alone/online/automatic control | |

| security measures | Electrical interlock, fall arrest device | |

| Standard | JB/T7013-93 | |

| payload | Max 1000KG | |

| cargo inspection | Photoelectric Sensors | SICK/P+F |

| roller | 76 double chain roller | |

| lifting chain | Donghua Chain | |

| bearing | General bearings: Harbin shaft key bearings: NSK | |

| running speed | Conveying speed: 16m/min, lifting speed: 6m/ min | |

| Surface Treatment and Coating | Pickling, phosphating, spraying | |

| noise control | ≤73dB | |

| surface coating | computer gray | Attached swatches |

main structure and features

Frame: 5mm carbon steel bent plate is used as column, and the outside is sealed with steel plate;

Lifting part:

A lifting frame is installed on the top of the hoist, the frame is made of carbon steel, and the lifting motor drives the lifting sprocket assembly to work through the chain.

Loading platform:

Made of carbon steel. The loading platform is equipped with a standard conveyor.

working principle:

The lifting motor drives the loading platform to complete the lifting work; the conveyor on the loading platform can make the goods enter and exit the elevator smoothly.