-

AMR

AMR trolley, it is a transport vehicle equipped with automatic guidance devices such as electromagnetic or optical, which can travel along the prescribed guiding path, has safety protection and various transfer functions. In industrial applications, it is a transport vehicle that does not require a driver. Its power source is a rechargeable battery.

Submerged AMR: sneak into the bottom of the material truck, and automatically mount and separate to realize material delivery and recycling operations. Based on various positioning and navigation technologies, automatic transport vehicles that do not require human driving are collectively referred to as AMR.

-

Palletizer

The palletizer is the product of the organic combination of machinery and computer programs,it Improves the efficiency of modern production. Palletizing machines are widely used in the palletizing industry. Palletizing robots can greatly save labor cost and floor space.

The palletizing robot is flexible, precise, fast, efficient, stable and efficient.

The palletizing robot system uses a coordinate robot device, which has the advantages of small footprint and small volume. The idea of establishing an efficient, efficient and energy-saving fully automated block machine assembly line can be realized.

-

Tray folding machine

Tray folding machine is an automatic equipment, which is also called code tray machine, it’s used in tray conveying system, combined with various conveyors, to distribute empty trays to the conveying line. The tray folding machine is used to stack single pallets into pallets stacking, including: pallet stacking support structure, pallet lifting table, load sensor, pallet position detection, open/close robot sensor, lift, lower, central position switch.

-

RGV

RGV stands for Rail Guide Vehicle, is also called a trolley. RGV is used in warehouses with various high-density storage methods, and the aisles can be designed according to any length to increase the storage capacity of the entire warehouse. In addition, when working, you can also take advantage of the fact that the forklift does not need to enter the lane way, combined with the rapid movement of the trolley in the lane way, it can effectively improve the operational efficiency of the warehouse and make it more safety.

-

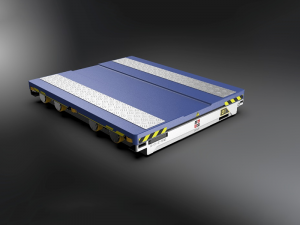

4D shuttle systems standard type

As the core equipment of the four-way car intelligent intensive warehouse, the vertical and horizontal car mainly consists of rack assembly, electrical system, power supply system, drive system, jacking system, sensor system, etc.

-

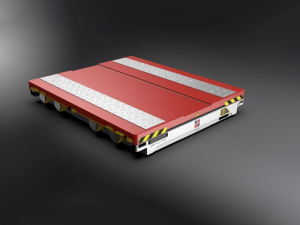

4D shuttle systems for low temperature

The structure of the low-temperature version of the crossbar is basically the same as that of the standard version. The main difference lies in the different operating environments. The low-temperature version of the crossbar is mainly used in the environment of – 30 ℃, so its internal material selection is very different. All internal components have low temperature resistance , the battery is also a low-temperature high-efficiency battery, which can support charging in a -30 °C environment. In addition, the internal control system has also been sealed to prevent condensation water when the maintenance is out of the warehouse.

-

4D shuttle systems for high speed application

The mechanism of the high-speed version of the vertical and horizontal car is basically the same as that of the ordinary vertical and horizontal car, the main difference lies in the improvement of the walking speed. In view of the relatively regular and stable pallet goods, in order to improve the overall efficiency of the project and reduce the number of crossbars used, a high-speed version of the crossbar is proposed. The walking speed index is twice that of the standard version, and the jacking speed remains unchanged. In order to improve safety, a safety laser is equipped on the equipment to prevent danger from high-speed operation.

-

4D shuttle systems for heavy load application

The mechanism of the heavy-duty crossbar is basically the same as that of the standard version, the main difference is that its load capacity is greatly improved. Its carrying capacity will reach nearly twice that of the standard version, and correspondingly, its corresponding running speed will also decrease. Both walking and jacking speeds will decrease.

-

Dense Racking for 4D shuttles

The four-way intensive warehouse shelf is mainly composed of rack pieces, Sub-channel crossbeams, Sub-channel tracks, horizontal tie rod devices, Main channel crossbeams, Main channel tracks, Connection of racks and ground, adjustable feet, back pulls, protective nets, maintenance ladders, The main material of the shelf is Q235/Q355, and the raw materials of Baosteel and Wuhan Iron and Steel are selected and formed by cold rolling.

-

High speed hoisting system

The reciprocating pallet elevator is mainly composed of the main parts such as the driving device, the lifting platform, the counterweight balance block, the outer frame, and the outer mesh.

-

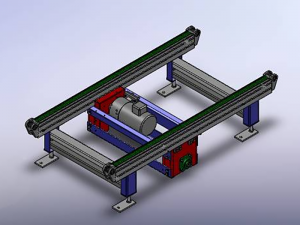

Information 4D shuttle conveyor system

The motor drives the drive shaft through the transmission group, and the drive shaft drives the conveying chain to realize the conveying function of the pallet.

-

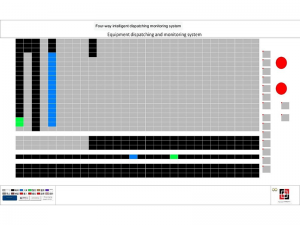

WCS-Warehouse Control System

The WCS system is responsible for the scheduling between the system and the equipment, and sends the commands issued by the WMS system to each equipment for coordinated operation. There is continuous communication between the equipment and the WCS system. When the equipment completes the task, the WCS system automatically performs data posting with the WMS system.